Engineering Fabrication

The Aviation and Defense communities’ ever-changing market demands require our team to continually enhance and develop our capabilities thru ongoing improvements to our current infrastructure.

Regularly planning and scheduling to add additional resources within the supply chain to address any and all requirements.

Core Competencies Include:

• Tight Tolerance Machining

• Forging and Casting

• Structures

• Sheet Metal, Metals, and Plastics

A snap shot of the process over all would look like:

Hurricane is compliant meeting and exceeding industries current requirements for control of digital product definition data and software. Boeing had reached consensus on a common process for controlling the transfer of digital product definition to suppliers which is outlined into 4 core sections.

- Section A of the checklist is used to perform a basic Digital Product Definition (DPD) capability verification.

- Section B is used to perform Model Based Definition (MBD) capability verification.

- Section C is used for Coordinate Measurement System (CMS) capability verification.

- Section D is used to perform Plotter capability verification.

Hurricane has audited and found to be compliant with this operating model while continuing to improve since 2015 Resources including:

- On Site and mobile FARO arm capabilities

- On site and mobile FARO laser tracker capabilities

- Complete sets of calibrated tools including but not limited to radius gauges, height gauges, & calipers

- Calibrated surface plate

- Full time quality manager/Engineering Services

- CAD software including but not limited to Solid Works Dassaut System

Quality Management System

Hurricane Aerospace Solutions maintains and continually improves a registered Quality Management System to AS9100 REV D and AC-00-56 REV B. Hurricane Aerospace Solutions, Inc. has already integrated an extensive FOD program within our facility to meet and/or exceed client requirements. Hurricane has integrated a formal Counterfeit Electronics Parts Avoidance program accepted by Boeing and NASA.

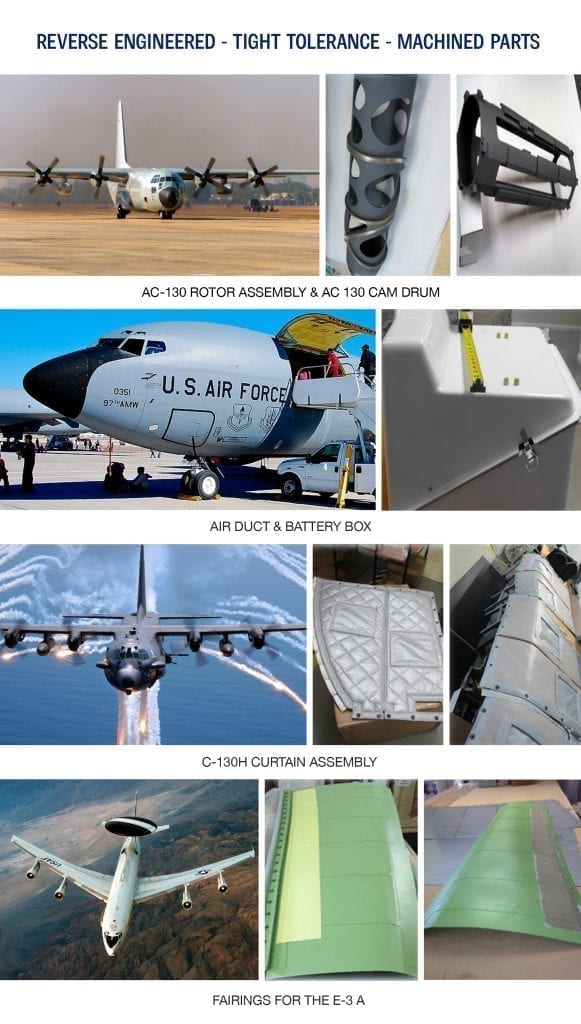

We have successfully delivered various manufactured items for many different aerospace and defense platforms in many categories such as:

Manufacturing NAICS Codes

- 331221 – Rolled Steel Shape Manufacturing

- 332311 – Prefabricated Metal Building and Component Manufacturing

- 332312 – Fabricated Structural Metal Manufacturing

- 332613 – Spring Manufacturing

- 332618 – Other Fabricated Wire Product Manufacturing

- 332710 – Machine Shops

- 332721 – Precision Turned Product Manufacturing

- 332722 – Bolt, Nut, Screw, Rivet, and Washer Manufacturing

- 332999 – All Other Miscellaneous Fabricated Metal Product Manufacturing

- 336413 – Other Aircraft Parts and Auxiliary Equipment Manufacturing

- 325212 – Synthetic Rubber Manufacturing

- 325510 – Paint and Coating Manufacturing

- 325520 – Adhesive Manufacturing

- 326220 – Rubber and Plastics Hoses and Belting Manufacturing

- 326291 – Rubber Product Manufacturing for Mechanical Use

- 326299 – All Other Rubber Product Manufacturing

- 327910 – Abrasive Product Manufacturing

- 315210 – Cut and Sew Apparel Contractors

- 315990 – Apparel Accessories and Other Apparel Manufacturing

- 622110 – General Medical and Surgical Hospitals